Introduzione del Mulino a cestello

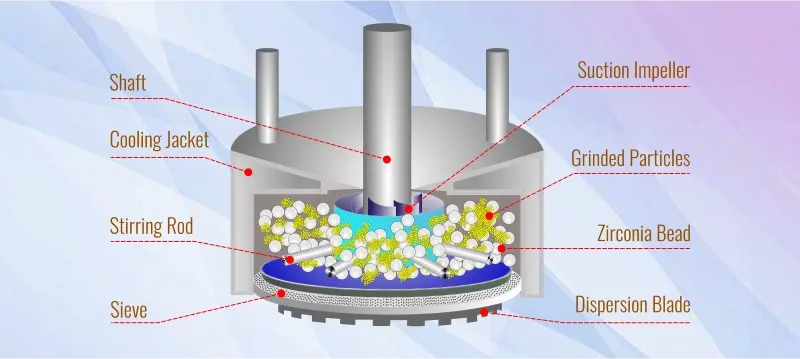

Un mulino a cestelli è un tipo di attrezzatura per la macinazione a umido utilizzata per macinare e disperdere materiali in un mezzo liquido. È costituito da un contenitore fisso, detto cestello, che ospita un albero rotante interno con lame forate o setacci. All'interno del cestello vengono contenuti i corpi macinanti (solitamente perle ceramiche) ed il prodotto da lavorare viene immesso nel mulino. Durante il funzionamento, il rotore ruota ad alta velocità, creando forze di taglio che distruggono efficacemente le particelle mentre il mezzo fornisce la macinazione ad impatto. Questa doppia azione garantisce un'efficace riduzione delle dimensioni e una dispersione uniforme di pigmenti, riempitivi e altri solidi in vernici, rivestimenti, inchiostri e varie formulazioni chimiche.

Il mulino a cestelli di SeFluid è una sorta di rettificatrice multifunzionale. Possiede sia la funzione di macinazione che quella di dispersione. Con proprietà di risparmio energetico, alta efficienza e facile manutenzione.

specifica

Energia

5,5-75 kW

Capacità batch

50-1200 litri

perlina

0,8-2,5 mm

Materiale

SS304, SS316

Come funziona un mulino a cestini

Un mulino a cestelli è una macchina di macinazione e dispersione che combina i processi di macinazione e dispersione in un'unica unità. Ecco come funziona:

- Progetto: Il nucleo di un mulino a cestelli è costituito da un contenitore cilindrico fisso o "cesto" con pareti forate, che contiene un albero agitatore dotato di pale o dischi sul fondo. Questo albero ruota all'interno del cestello.

- Operazione: Il prodotto da lavorare (una sospensione di solidi in liquido) viene riempito nel cestello. All'interno del cestello sono presenti mezzi di macinazione, solitamente perle o sfere di ceramica, che riempiono una parte significativa del volume.

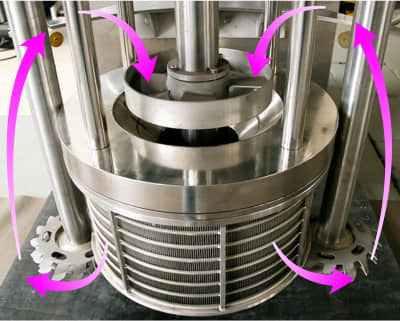

- Processo di fresatura: Quando la macchina viene attivata, l'albero dell'agitatore inizia a ruotare ad alta velocità. Mentre gira, le lame creano una potente aspirazione che trascina il prodotto dall'alto attraverso il letto del supporto e poi lo espelle attraverso i fori nella parete del cestello.

- Dispersione e macinazione: I mezzi di macinazione nel cestello macinano le particelle solide quando entrano in collisione con esse sotto forze di taglio e impatto. Contemporaneamente, il prodotto in transito viene sottoposto ad un'intensa azione di taglio da parte delle lame in rapido movimento, portando ad un'efficace dispersione delle particelle.

- Ricircolo: Il prodotto esce dal carrello ma non esce immediatamente dal sistema. Viene invece ricircolato nel cestello più volte fino al raggiungimento della riduzione granulometrica e dell'omogeneità desiderate.

- Elaborazione controllata: I parametri di processo come la velocità di rotazione, la quantità di mezzi di macinazione e il tempo di lavorazione possono essere regolati in base ai requisiti applicativi specifici per risultati di macinazione e dispersione ottimali.

In sintesi, il mulino a cestelli macina e disperde in modo efficiente pigmenti, riempitivi e altri materiali in mezzi liquidi attraverso una combinazione di impatto meccanico dei mezzi di macinazione e forze di taglio esercitate dall'agitatore, garantendo una distribuzione uniforme delle dimensioni delle particelle e una migliore qualità del prodotto.

Capolavoro del Mulino di cesti

- Cestino: Il cuore della testata di lavoro è il cestello forato, che può essere realizzato in acciaio inox o altri materiali durevoli. Questo cestello presenta numerosi piccoli fori che permettono il passaggio del materiale lavorato contenendo al suo interno il materiale macinante.

- Albero agitatore: All'interno del cestello è presente un albero agitatore dotato all'estremità inferiore di pale o dischi. Questo albero ruota ad alta velocità per creare intense forze di taglio per una dispersione efficace.

- Mezzi di macinazione: Il cestello contiene un volume sostanziale di mezzi di macinazione, tipicamente perle o sfere di ceramica, che macinano le particelle solide nella sospensione liquida quando entrano in collisione tra loro e con il prodotto sotto l'influenza dell'agitatore rotante.

- Perforazioni: Le perforazioni nella parete del cestello sono fondamentali in quanto facilitano il passaggio della miscela di prodotto attraverso i corpi macinanti. La dimensione di queste aperture determina la distribuzione granulometrica del prodotto finale, con fori più piccoli che consentono una macinazione più fine.

- Sistema di tenuta: Per evitare perdite di prodotto e garantire il contenimento dell'ambiente di macinazione, la testa di lavoro spesso include una tenuta meccanica o una doppia tenuta meccanica tra la parte stazionaria (cestello) e l'albero rotante dell'agitatore.

- Sistema di raffreddamento/riscaldamento: Alcuni mulini a cestello avanzati possono incorporare elementi di raffreddamento o riscaldamento all'interno della testa di lavoro per controllare la temperatura durante la lavorazione, soprattutto per i prodotti sensibili al calore.

Caratteristiche della serie di mulini a cestello SEBM

La serie di mulini a cestello SEBM di SeFluid rappresenta una soluzione innovativa e versatile per i processi di macinazione e dispersione in vari settori. Questi mulini sono stati progettati meticolosamente per integrare due operazioni critiche in un'unica macchina, migliorando così l'efficienza, riducendo i tempi di fermo e garantendo una qualità costante del prodotto. Di seguito sono riportate le caratteristiche salienti che definiscono le eccezionali prestazioni e l'adattabilità delle nostre attrezzature.

- Integrazione a doppio processo: Questo macchinario avanzato esegue simultaneamente sia le attività di macinazione che quelle di dispersione, eliminando la necessità di apparecchiature separate.

- Facilità di pulizia e cambio rapido del materiale: Il cestello di macinazione è progettato con un'interfaccia intuitiva, che consente una pulizia e un cambio del materiale rapidi e senza sforzo, favorendo così un'elevata produttività.

- Strutture della testa di lavoro personalizzabili: Viene offerta una selezione di diverse configurazioni della testa di lavoro per soddisfare le diverse e specifiche esigenze in diverse applicazioni e settori.

- Componenti bilanciati di precisione: L'albero principale ad alta velocità e la testa del cestello, accoppiati con una puleggia che ha superato rigorosi test di equilibrio statico e dinamico, garantiscono un funzionamento regolare e una lunga durata.

- Sistema di separazione ottimizzato: Con una piastra a maglie di precisione che vanta un'area di troppopieno più ampia del 30%, garantisce una migliore separazione delle perle dal mezzo, migliorando l'efficacia complessiva del processo.

- Meccanismi di sollevamento flessibili: Gli utenti possono scegliere tra sistemi di sollevamento idraulici, pneumatici o meccanici, tutti in grado di garantire un movimento SU/GIÙ affidabile e senza interruzioni per i componenti.

- Opzioni di serraggio versatili: Che si tratti di sistemi di bloccaggio a nastro, di bloccaggio manuale o di bloccaggio pneumatico, queste opzioni offrono comodità operativa su misura in base alle preferenze individuali.

- Velocità di elaborazione efficiente: La serie SEBM offre una notevole efficienza, ottenendo risultati di macinazione ottimali in tempi di lavorazione brevi, riducendo al minimo i cicli di produzione.

- Controllo preciso della velocità: Un avanzato sistema di controllo della conversione della frequenza consente la regolazione continua della velocità, consentendo un controllo preciso sui processi di macinazione e dispersione.

- Costruzione durevole: Costruiti con un robusto design del cilindro a doppio strato, questi mulini impediscono qualsiasi perdita di olio idraulico anche dopo un uso prolungato, garantendo prestazioni durature e affidabilità.

In generale, la serie di mulini a cestello SEBM di SeFluid combina tecnologia all'avanguardia con funzionalità pratiche per offrire uno strumento potente e adattabile per i processi di macinazione e dispersione industriali. La sua combinazione unica di funzionalità garantisce un utilizzo efficiente delle risorse, flessibilità e qualità del prodotto superiore, rendendolo la scelta ideale per le aziende che cercano una soluzione all'avanguardia per le proprie esigenze di produzione. Investendo nella serie SEBM Basket Mill, gli utenti possono aspettarsi una maggiore produttività, costi di manutenzione ridotti e affidabilità duratura per tutto il ciclo di vita dell'attrezzatura.

Sistema di raffreddamento della testa di lavoro del mulino a cestelli

Il sistema di raffreddamento della testa di lavorazione di un mulino a cestelli è un componente essenziale per mantenere temperature operative ottimali e prevenire il surriscaldamento durante il processo di macinazione e dispersione. Il sistema è progettato per gestire il calore generato dall'attrito tra i mezzi di macinazione, le particelle di prodotto e le pareti del cestello, che può influire sulla qualità del prodotto, sulla viscosità e sulle prestazioni della macchina. Ecco come funziona tipicamente il sistema di raffreddamento nella testa di lavoro di un mulino a cestelli SeFluid:

- Giacca di raffreddamento: Una camicia di raffreddamento circonda la testa portapezzo, che comprende la camera di macinazione (cestello) e talvolta il motore o i componenti di azionamento. Questa camicia può essere riempita con acqua, liquido refrigerante o altri fluidi regolatori della temperatura che circolano attraverso di essa per assorbire e dissipare il calore.

- Sistema di raffreddamento a circuito chiuso: Il mezzo di raffreddamento scorre attraverso la camicia in un circuito chiuso, spesso raffreddato esternamente da un refrigeratore o da uno scambiatore di calore. Ciò garantisce un raffreddamento coerente ed efficiente senza contaminazione del materiale lavorato.

- Controllo della temperatura: Il sistema di raffreddamento può includere sensori di temperatura per il monitoraggio e il controllo in tempo reale. Questi sensori trasmettono i dati a un pannello di controllo automatizzato, consentendo agli operatori di regolare la velocità di raffreddamento in base ai requisiti specifici del processo ed evitare il raffreddamento eccessivo o insufficiente.

- Isolamento: In alcuni progetti, la testa di lavoro potrebbe anche essere isolata per ridurre al minimo la perdita di calore quando il raffreddamento non è necessario o per mantenere una temperatura interna stabile durante le operazioni di riscaldamento.

- Caratteristiche di sicurezza: Per prevenire il congelamento o l'ebollizione del fluido di raffreddamento, nel sistema sono integrate misure di sicurezza come termostati e valvole limitatrici di pressione.

- Ottimizzazione dei processi: Mantenendo una temperatura stabile all'interno della testa di lavoro, il sistema di raffreddamento aiuta a ottimizzare il processo di macinazione, garantendo una riduzione consistente delle dimensioni delle particelle, evitando la degradazione termica dei materiali sensibili e prolungando la durata sia dei mezzi di macinazione che dell'attrezzatura stessa.

In sintesi, il sistema di raffreddamento nella testa di lavorazione di un mulino a cestelli svolge un ruolo fondamentale nella gestione della dinamica termica del processo di macinazione, salvaguardando così la qualità del prodotto e migliorando l'efficienza complessiva e la longevità della macchina.

Motivi per scegliere i mulini a cestello SeFluid

- Ingegneria di precisione I nostri mulini sono dotati di componenti progettati con precisione, tra cui un design all'avanguardia del cestello in rete che garantisce una separazione superiore delle perle e del mezzo, portando a una riduzione delle dimensioni delle particelle più fine e a dispersioni omogenee.

- Configurazioni personalizzabili Realizzati su misura per le vostre esigenze specifiche, i mulini a cestello di SeFluid offrono varie strutture della testa di lavoro per adattarsi a diversi materiali e applicazioni, fornendo una flessibilità che non è seconda a nessuno.

- Gestione avanzata della temperatura Sperimenta la lavorazione a temperatura controllata con i nostri efficienti sistemi di raffreddamento che mantengono condizioni ottimali all'interno della testa di lavoro, proteggendo i materiali sensibili dal degrado e garantendo al contempo un funzionamento affidabile della macchina.

- Design intuitivo Con cestelli facili da pulire e funzionalità di cambio rapido del materiale, i mulini a cestelli SeFluid garantiscono tempi di fermo minimi e manutenzione semplificata, massimizzando l'efficienza operativa complessiva.

- Controllo della velocità all'avanguardia Dotati di un controllo avanzato della conversione della frequenza, i nostri mulini consentono regolazioni continue della velocità, fornendo un controllo preciso sul processo di macinazione per una finezza e una consistenza ottimali.

- Costruzione robusta e affidabile I mulini a cestello di SeFluid sono costruiti pensando alla durabilità. Gli alberi principali ad alta velocità, la struttura bilanciata e i robusti meccanismi di sollevamento (idraulici, pneumatici o meccanici) garantiscono prestazioni fluide e affidabili per l'intero ciclo di vita dell'attrezzatura.

- La sicurezza prima Le caratteristiche di sicurezza come il design del cilindro a doppio strato prevengono le perdite di olio e i sistemi di bloccaggio sicuri garantiscono la sicurezza dell'operatore e garantiscono l'integrità dell'ambiente di lavorazione.

- Produttività migliorata Trasforma in modo efficiente le materie prime in prodotti finemente lavorati in tempi record con i mulini a cestello di SeFluid, che offrono produttività ed efficienza dei costi eccezionali.

- Assistenza clienti completa Noi di SeFluid siamo orgogliosi del nostro impegno per la soddisfazione del cliente. Il nostro team dedicato fornisce guida esperta, supporto per l'installazione e servizio post-vendita per garantire che il vostro investimento nei nostri mulini a cestello produca il massimo rendimento.

Applicazioni dei mulini a cestello SeFluid

I mulini a cestelli di SeFluid sono apparecchiature di lavorazione versatili con un'ampia gamma di applicazioni in vari settori. Eccellono nella macinazione, dispersione e omogeneizzazione di materiali che richiedono una riduzione delle dimensioni delle particelle e una distribuzione uniforme all'interno di mezzi liquidi. Di seguito sono riportati alcuni settori chiave e le loro applicazioni specifiche per i mulini a cestelli:

- Industria delle vernici e dei rivestimenti: I mulini a cestello sono ampiamente utilizzati per disperdere pigmenti, riempitivi e altri additivi nella matrice della vernice. Garantiscono un'eccellente forza del colore, stabilità e proprietà reologiche migliorate.

- Inchiostri da stampa: Per la produzione di inchiostri da stampa a base acqua o solvente, i mulini a cestello forniscono una dispersione precisa di pigmenti e coloranti, ottenendo stampe di alta qualità con consistenza cromatica ottimale.

- Adesivi e Sigillanti: Questi mulini aiutano a ottenere dimensioni delle particelle fini e viscosità costante nelle formulazioni di adesivi e sigillanti, migliorando le prestazioni del prodotto, la forza di adesione e la durata di conservazione.

- Prodotti farmaceutici: Nella produzione farmaceutica, i mulini a cestello vengono utilizzati per la macinazione a umido di API (principi farmaceutici attivi) ed eccipienti, garantendo miscele omogenee cruciali per l'efficacia dei farmaci e la sicurezza dei pazienti.

- Cosmetici: L'industria dei cosmetici utilizza mulini a cestello per macinare e miscelare pigmenti, emollienti e altri ingredienti nei prodotti per il trucco, la cura della pelle e dei capelli per ottenere una consistenza morbida e sospensioni stabili.

- Cibo e bevande: Per coloranti alimentari, aromi e agenti addensanti, i mulini a cestello offrono una riduzione controllata delle dimensioni delle particelle e una dispersione superiore, migliorando la qualità, l'aspetto e il gusto del prodotto.

- Prodotti chimici e lubrificanti: Nella sintesi chimica e nella formulazione di lubrificanti, i mulini a cestello sono efficaci per scomporre i solidi e creare dispersioni stabili.

- Ceramica e Vetro: Durante la preparazione dei fanghi per la produzione di ceramica e vetro, i mulini a cestello garantiscono una distribuzione uniforme delle particelle e una ridotta agglomerazione.

- Elettronica: Nel settore delle paste elettroniche, i mulini a cestello svolgono un ruolo significativo nella macinazione di precisione e nella miscelazione di materiali conduttivi come argento, rame e grafite per circuiti stampati.

I mulini a cestelli di SeFluid trovano applicazione ovunque sia necessario un processo di macinazione, dispersione e deagglomerazione efficiente ed efficace, in particolare nelle industrie che richiedono un controllo rigoroso sulla distribuzione delle dimensioni delle particelle e sulla purezza del prodotto.

Richiesta di offerta

NOTIZIE

CONTATTO

N. 10, Jinhai Rd, Hefei, Cina 201400

Telefono: +86 156 6910 1862

Fax: +86 551 5843 6163

potere.diulfesobfsctd-68e042@selas